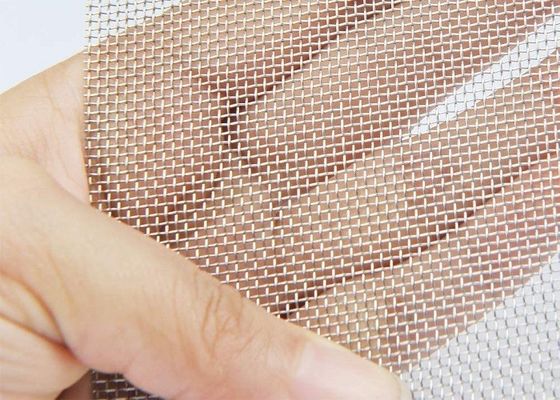

Stainless Steel Fine Woven Wire Mesh for Rotary Vibrating Screen Separator For Liquid Filter

Woven wire mesh is often used as the vibrating screen, this is one of the most important uses of woven mesh. It contacts directly the material, and the material could be mild steel, galvanized steel, high manganese steel, stainless steel, or other alloys. Besides, the non-metal wire mesh could also be used as the vibrating screens, such as fiberglass, polyester, nylon, etc.

Stainless Steel material has 201, 302, 304, 304L, 316, 316L, and many other related stainless alloys. The stainless steel woven wire mesh could be used so widely, especially for filtration and vibrating, mainly because of the following features: superior resistance against acid, alkali, corrosion, etc, and high tensile strength, toughness, and strong abrasive. It even could work well in an environment with 800-1150 degree high temperatures.

The Rotary Vibrating Screen Separator is with a high-performance stainless steel fine wire mesh installed on rotary vibrating screen separator machines. It is mainly used to grade, and remove impurities and filter the powders, particles, and slurry materials in various industries' applications. Its tightly controlled aperture size is essential to achieving a reliable, efficient screening outcome.

Here are some very commonly used stainless steel wove wire mesh specifications, just for your reference. Other specifications, sizes, and woven types are made to order. Please contact our sales team to discuss this.

| Commonly Used Coarse Mesh Specifications for Rotary Vibrating Screen |

| Mesh Count |

Wire Diameter. Mm |

Opening mm |

Open Area (%) |

| 3 |

1.6 |

6.87 |

65.8 |

| 4 |

1.2 |

5.15 |

65.8 |

| 5 |

1.6 |

3.48 |

46.9 |

| 6 |

0.9 |

3.33 |

62 |

| 8 |

1 |

2.18 |

46.9 |

| 8 |

1.2 |

1.98 |

38.7 |

| 10 |

0.5 |

2.04 |

64.5 |

| 10 |

0.6 |

1.94 |

58.3 |

| 12 |

0.65 |

1.47 |

48 |

| 14 |

0.5 |

1.31 |

52.5 |

| 16 |

0.4 |

1.19 |

56 |

| 18 |

0.4 |

1.01 |

51.3 |

| 20 |

0.3 |

0.97 |

58.3 |

| 20 |

0.5 |

0.77 |

36.8 |

| 24 |

0.36 |

0.7 |

43.5 |

| 30 |

0.3 |

0.55 |

41.7 |

| 35 |

0.25 |

0.5 |

44.4 |

| 40 |

0.25 |

0.39 |

36.8 |

| 45 |

0.25 |

0.31 |

31 |

| 50 |

0.2 |

0.31 |

36.8 |

| 60 |

0.16 |

0.26 |

38.7 |

| 60 |

0.18 |

0.24 |

33 |

| Commonly Used Fine Mesh Specifications for Rotary Vibrating Screen |

| Mesh Count |

Wire Diameter (mm) |

Aperture Width (mm) |

Open Area (%) |

| 65 |

0.1 |

0.287 |

54.6 |

| 70 |

0.1 |

0.261 |

52 |

| 80 |

0.14 |

0.18 |

31.6 |

| 100 |

0.1 |

0.16 |

37.9 |

| 110 |

0.09 |

0.14 |

37.1 |

| 120 |

0.09 |

0.12 |

32.7 |

| 140 |

0.06 |

0.12 |

44.4 |

| 150 |

0.06 |

0.11 |

41.9 |

| 200 |

0.05 |

0.08 |

37.9 |

| 200 |

0.053 |

0.074 |

34 |

| 250 |

0.04 |

0.063 |

37.4 |

| 325 |

0.035 |

0.043 |

30.4 |

| 400 |

0.027 |

0.036 |

32.7 |

| 450 |

0.027 |

0.03 |

27.7 |

| 500 |

0.025 |

0.025 |

25 |

Attention

Be careful of the cutting sharp edge, and avoid getting hurt while open and use.

Before you order your mesh, please first check out our stock list, where we put our over-run bargain rolls at lower prices.

King De Long Wire Mesh can manufacture not only woven wire mesh but also welded wire mesh with the specified wire and mesh size you required. Should you have a particular specification in mind, please contact us to discuss your requirements.

For your reference, some photos of our products and factory are listed here, please check.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!