Punching Plate for Building Exterior Wall

The building exterior wall perforated plate is a kind of perforated mesh, which is mainly used in the fields of real estate construction and decoration. Since the real estate industry needs better rigidity of the perforated plate for the exterior wall of the building, we usually use stainless steel plate or low carbon steel plate as the main raw material in many forms of materials used in deep processing. Moreover, in many buildings and buildings, large-area perforated mesh design is used to make metal curtain walls, which highlight the existing modern fashion and majestic momentum. Aluminum plate or aluminum alloy raw materials are the main materials.

| In Coil |

In Plate |

| Thickness:0.2mm-1mm |

Thickness:0.2mm-20mm |

| Aperture:3mm-10mm |

Aperture:0.25mm-200mm |

| Length:20m |

Width*Length:≤1.5m*5m |

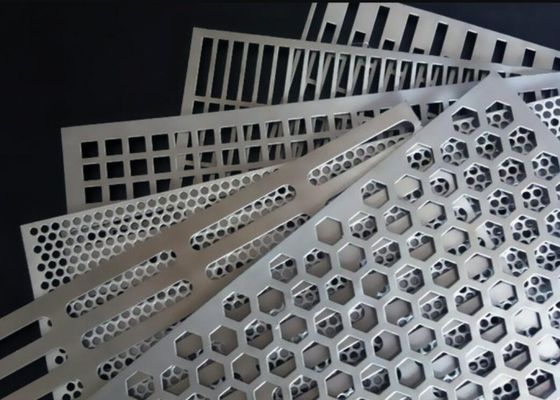

Building Exterior Wall Punched Metal Sheet 1.5m*5m High Durability,The hole type, hole diameter and hole distance of the building exterior wall punching plate can be customized according to specific needs. Perforated mesh products of different materials can be used for different surface treatments, highlighting the uniqueness and representativeness of the decorative effect. For example: ceilings, partitions, curtain walls, sound insulation panels, railings, spiral stairs, balconies, etc., you can see the perforated panels on the exterior walls of buildings. The main hole types of building exterior wall punching plates are rectangular holes, square holes, diamond holes, round holes, oblong holes, hexagonal holes, cross holes, triangular holes, long waist holes, plum blossom holes, scale holes, pattern holes, and eight-character holes. Net, herringbone hole, pentagram hole, irregular hole, drum hole, special-shaped hole, louver hole, etc.

The characteristics and advantages of the aluminum plate of the building exterior wall punching plate mainly include: 1. Simple and convenient installation, high hardness and toughness. 2. Not easy to be corroded. 3. Good manufacturability; the aluminum plate can form many special-shaped shapes before processing, and the plane is clean. 4. The surface is smooth and the color tone can be exchanged; in order to achieve uniform adhesion between the paint and the aluminum plate, we adopt advanced electrostatic spraying technology, with various colors, providing customers with a large choice of colors. 5. It is not easy to be stained with dust, and it is very simple to clean and organize; the scope of application of the aluminum plate is very popular among the public, and the non-adhesiveness of the fluorine coating film makes it difficult for the surface of the aluminum plate to be stained with strong pollutants. There is a strong simple cleaning function. 6. The simple construction and installation function allows the builder to greatly reduce the complexity of the work. Before the aluminum plate is processed, there is no need to cut it on the construction site, just fix it on the skeleton. 7. It has great recycling and environmental protection characteristics; the recyclability of aluminum plate reaches 100%, which is different from decorative materials such as glass, stone, ceramics, aluminum-plastic panels, etc., and has a high recovery value.

KDL Certificated

KDL Workshop

FAQ

Q: Can perforated sheet be plastic coated?

A: We don’t plastic coat perforated sheet, however we can perforate a plastic sheet.

Q: Why is perforated sheet protected with a thin layer of oil?

A: Lubricating oil is used to reduce the friction during the perforating process.

Q: Can perforated sheet be formed after perforating?

A: We can shear and form perforated sheet to any specification needed.

Q: What opening types are most common in perforated sheet?

A: Round, rectangular, and slotted perforated sheet are very popular options. See our decorative perforated sheet for more unique styles.

Q: Which perforated sheet materials are rust resistant?

A: Perforated aluminum, stainless steel, and galvanized perforated steel are the most rust resistant materials that we perforate.

Q: Why is perforated sheet commonly used?

A: Perforated sheet is used for a variety of applications because of the hole size options, percentage of open area, high strength-to-weight ratio, and aesthetic appeal.

Q: Can I choose the material type for my perforated metal sheet?

A: Yes, there are many material options for your perforated sheet order. Perforated steel comes in both stainless perforated steel and carbon perforated steel. You can also choose aluminum perforated sheet. If you need help deciding between perforated steel, perforated aluminum, and other material options, you can learn more in our Perforated Metal Catalog.

Frequently Asked Questions

Q: Are you trading company or manufacturer ?

A: Kingdelong is the factory,and welcome to visite our factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. If not in stock,then maybe15-20 days, it is according to your order quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, of course we could offer the sample for free charge while you pay the cost of freight.

If you have another question, please feel free to contact our sales team.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!