Product Description:

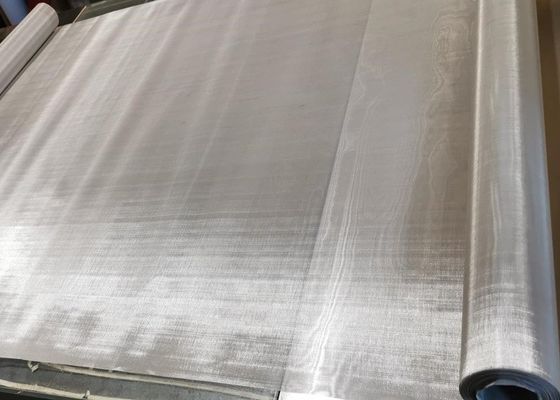

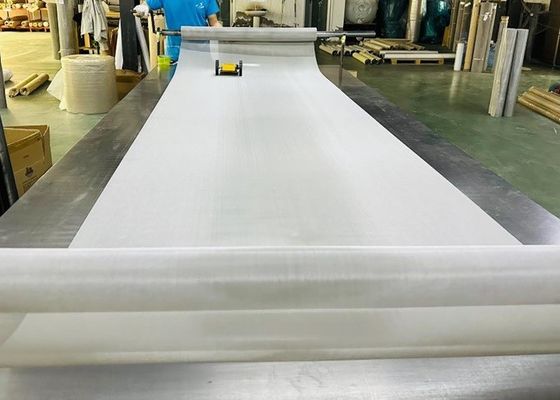

Stainless steel wire mesh screen is a versatile material commonly used in various applications like filtration, protection, and separation. The mesh is made of stainless steel wires woven together to form a uniform and durable surface. It offers excellent corrosion resistance, high tensile strength, and good stability in different environmental conditions. Stainless steel wire mesh screens are used in industries such as mining, food processing, pharmaceuticals, architecture, and many others due to their durability and reliability.

Stainless steel wire mesh screens come in various types, including plain weave, twill weave, dutch weave, and welded mesh. The plain weave is the simplest and most common type, consisting of wires woven in a crisscross pattern. Twill weave has a diagonal pattern, providing higher strength and stability. Dutch weave has different wire diameters for the warp and weft wires, offering excellent filtration capabilities. Welded mesh is made by welding the intersections of wires, creating a strong and stable mesh.

These wire mesh screens can be customized in terms of mesh size, wire diameter, and screen size to suit specific application requirements. They are used for purposes such as filtering liquids and gases, separating solid particles, protecting machinery from debris, and ensuring safety in industrial settings. Stainless steel wire mesh screens are known for their longevity, resistance to corrosion, and easy maintenance, making them a popular choice across various industries.

Features:

1. Corrosion Resistance: Stainless steel wire mesh screens are highly resistant to corrosion, making them suitable for use in a wide range of environments, including those with exposure to moisture, chemicals, and extreme temperatures.

2. Strength and Durability: Stainless steel wire mesh screens are known for their high tensile strength and durability, making them ideal for applications where mechanical strength is crucial.

3. Versatility: Stainless steel wire mesh screens are available in various weave patterns, wire diameters, and opening sizes, making them versatile for a wide range of applications. They can be customized to meet specific requirements.

4. High-Temperature Resistance: Stainless steel wire mesh screens can withstand high temperatures, making them suitable for applications involving heat or fire.

5. Easy to Clean: Stainless steel wire mesh screens are easy to clean and maintain, making them ideal for applications where hygiene is important, such as in food processing or pharmaceutical industries.

6. Good Visibility and Airflow: The open weave design of stainless steel wire mesh screens allows for good visibility and airflow, making them suitable for applications where transparency and ventilation are important.

7. Chemical Resistance: Stainless steel wire mesh screens are resistant to many chemicals, making them suitable for applications where exposure to corrosive substances is a concern.

8. Longevity: Stainless steel wire mesh screens have a long service life, making them a cost-effective solution for many applications.

Overall, stainless steel wire mesh screens are a popular choice for various industries due to their durability, corrosion resistance, and versatility.

Technical Parameters:

| Technical Parameters |

Values |

| Mesh Size |

0.03-50.8mm |

| Wire Diameter |

0.02mm-5mm |

| Weave Type |

Plain Weave, Twilled Weave, Dutch Weave |

| Length |

1m-300m |

| Mesh Count |

Plain Weave: Up to 400 Mesh

Twill Weave: 30 to 635 Mesh |

| Features |

Flat, Solid, Corrosion Resistance, Oxidation Resistance |

| Edge Treatment |

Raw Edge, Selvage |

| Aperture |

0.02-50.8mm |

| Material |

SS Wire 201, 304, 304L, 316, 316L, 431, 321 310, Monel/Inconel or other alloy, Etc. |

Applications:

Stainless steel wire mesh screens are versatile and find a wide range of applications across various industries due to their durability, corrosion resistance, and strength. Some common applications of stainless steel wire mesh screens include:

1. Filtration and Separation: Stainless steel wire mesh screens are widely used for filtration and separation purposes in industries such as oil and gas, water treatment, pharmaceuticals, food processing, and chemical processing. They can filter out particles of different sizes and impurities from liquids, gases, or solids.

2. Screening and Sifting: Stainless steel wire mesh screens are used for screening and sifting applications in industries such as mining, agriculture, construction, and recycling. They can separate materials of different sizes and grades efficiently.

3. Architectural and Decorative: Stainless steel wire mesh screens are used in architectural and interior design for decorative purposes. They can be used in wall cladding, ceilings, balustrades, and other design elements to create a modern and stylish look.

4. Security and Protection: Stainless steel wire mesh screens are utilized for security and protection purposes in windows, doors, fencing, and enclosures. They provide a strong barrier while allowing visibility and airflow.

5. Animal Enclosures: Stainless steel wire mesh screens are commonly used in zoos, aviaries, and animal enclosures to provide a secure and durable barrier while allowing for visibility and ventilation.

6. Heat and Flame Protection: Stainless steel wire mesh screens are used in applications that require heat and flame protection, such as in fireplaces, heat shields, and welding curtains.

7. EMI/RFI Shielding: Stainless steel wire mesh screens are used in electronic and telecommunications industries for electromagnetic interference (EMI) and radio frequency interference (RFI) shielding.

8. Industrial Sieving: Stainless steel wire mesh screens are used in industrial sieving machines for grading, sorting, and separating materials in processes such as powder coating, flour milling, and aggregate screening.

9. Insect and Pest Control: Stainless steel wire mesh screens are used in windows, doors, and vents to prevent insects and pests from entering buildings while allowing for ventilation.

10. Medical and Laboratory Applications: Stainless steel wire mesh screens are used in medical devices, laboratory equipment, and surgical instruments for filtration, sieving, and separation purposes.

These are just a few examples of the diverse applications of stainless steel wire mesh screens, showcasing their versatility and importance across various industries and settings.

Commonly Used Specifications of the Plain and Twilled Weave Types

| Mesh |

Wire Diameter |

Opening |

Open Area % |

Weight per sq.ft |

| 1 x 1 |

.063” |

.937” |

87.8 |

0.255 |

| .080” |

.920” |

84.6 |

0.411 |

| .105” |

.895” |

80.1 |

0.71 |

| .135” |

.865” |

74.8 |

1.177 |

| .162” |

.838” |

70.2 |

1.702 |

| .250” |

.750” |

56.3 |

4.124 |

| 3/4 x 3/4 |

.054” |

.696” |

86.1 |

0.249 |

| .063” |

.687” |

83.9 |

0.34 |

| .080” |

.670” |

79.8 |

0.549 |

| .105” |

.645” |

73.9 |

0.95 |

| .135” |

.615” |

67.2 |

1.581 |

| .162” |

.588” |

61.4 |

2.292 |

| .250” |

.500” |

44.4 |

5.623 |

| 2 x 2 |

.047” |

.453” |

81.2 |

0.284 |

| .054” |

.446” |

79.6 |

0.376 |

| .072” |

.428” |

73.3 |

0.671 |

| .092” |

.408” |

66.6 |

1.102 |

| .120” |

.380” |

57.8 |

1.896 |

| .148” |

.352” |

49.6 |

2.924 |

| .192” |

.308” |

37.9 |

5.055 |

| 3 x 3 |

.032” |

.301” |

81.5 |

0.197 |

| .035” |

.298” |

79.9 |

0.237 |

| .047” |

.286” |

73.6 |

0.428 |

| .063” |

.270” |

65.6 |

0.776 |

| .080” |

.253” |

57.6 |

1.264 |

| .105” |

.228” |

46.8 |

2.22 |

| .135” |

.198” |

35.3 |

3.776 |

| 4 x 4 |

.025” |

.225” |

81 |

0.161 |

| .028” |

.222” |

78.9 |

0.202 |

| .035” |

.215” |

74 |

0.317 |

| .047” |

.203” |

65.9 |

0.576 |

| .063” |

.187” |

56 |

1.048 |

| .080” |

.170” |

46.2 |

1.721 |

| .105” |

.145” |

33.6 |

3.062 |

| .135” |

.115” |

21.2 |

5.038 |

| 5 x 5 |

.032” |

.168” |

70.6 |

0.332 |

| .041” |

.159” |

63.2 |

0.549 |

| .054” |

.146” |

53.3 |

0.967 |

| .072” |

.128” |

41 |

1.764 |

| .092” |

.108” |

29.2 |

2.834 |

| .105” |

.095” |

22.6 |

3.787 |

| 6 x 6 |

.028” |

.139” |

69.6 |

0.305 |

| .035” |

.132” |

62.7 |

0.481 |

| .047” |

.120” |

51.8 |

0.882 |

| .063” |

.104” |

38.9 |

1.63 |

| .080” |

.087” |

27.2 |

2.591 |

| 7 x 7 |

.028” |

.115” |

64.8 |

0.358 |

| .035” |

.108” |

57.2 |

0.565 |

| .047” |

.096” |

45.2 |

1.042 |

| .063” |

.080” |

31.4 |

1.847 |

| 8 x 8 |

.017” |

.108” |

74.6 |

0.14 |

| .023” |

.102” |

66.6 |

0.27 |

| .028” |

.097” |

60.2 |

0.41 |

| .035” |

.090” |

51.8 |

0.651 |

| .047” |

.078” |

38.9 |

1.209 |

| .063” |

.062” |

24.6 |

2.163 |

| 9 x 9 |

.023” |

.088” |

62.7 |

0.311 |

| .032” |

.079” |

50.6 |

0.614 |

| .047” |

.064” |

33.2 |

1.382 |

| 10 x 10 |

.020” |

.080” |

64 |

0.261 |

| .023” |

.077” |

59.3 |

0.347 |

| .028” |

.072” |

51.8 |

0.521 |

| .035” |

.065” |

42.3 |

0.831 |

| .047” |

.053” |

28.1 |

1.484 |

| .063” |

.037” |

13.7 |

2.854 |

| 12 x 12 |

.018” |

.065” |

60.8 |

0.255 |

| .023” |

.060” |

51.8 |

0.422 |

| .028” |

.055” |

43.6 |

0.635 |

| .035” |

.048” |

33.2 |

1.021 |

| .047” |

.036” |

18.7 |

1.851 |

| 14 X 14 |

.017” |

.054” |

57.2 |

0.266 |

| .018” |

.053” |

55.1 |

0.299 |

| .020” |

.051” |

51 |

0.372 |

| .025” |

.046” |

41.5 |

0.593 |

| .032” |

.039” |

29.8 |

1.005 |

| .041” |

.030” |

17.6 |

1.65 |

| 16 x 16 |

.016” |

.047” |

55.4 |

0.271 |

| .018” |

.045” |

50.7 |

0.345 |

| .023” |

.040” |

39.9 |

0.577 |

| .028” |

.035” |

30.5 |

0.836 |

| .035” |

.028” |

19.4 |

1.366 |

| 18 x 14 |

.011” |

.045”/.060” |

70.6 |

0.102 |

| 18 x 18 |

.009” |

.047” |

70.4 |

0.095 |

| .017” |

.039” |

48.3 |

0.348 |

| .020” |

.036” |

41.1 |

0.49 |

| .025” |

.031” |

30.3 |

0.75 |

| .032” |

.024” |

18 |

1.294 |

| 20 x 20 |

.009” |

.041” |

67.2 |

0.105 |

| .014” |

.036” |

51.8 |

0.261 |

| .017” |

.033” |

43.6 |

0.391 |

| .020” |

.030” |

36 |

0.552 |

| .025” |

.025” |

25 |

0.85 |

| .028” |

.022” |

19.4 |

1.093 |

| 24 x 24 |

.0075” |

.034” |

67.4 |

0.088 |

| .010” |

.032” |

57.9 |

0.158 |

| .020” |

.022” |

27.1 |

0.648 |

| 26 x 26 |

.015” |

.024” |

37.3 |

0.402 |

| .017” |

.022” |

31.2 |

0.526 |

| .020” |

.019” |

23.1 |

0.713 |

| 28 x 28 |

.010” |

.026” |

51.8 |

0.186 |

| .0135” |

.022” |

38.6 |

0.349 |

| 30 x 30 |

.007” |

.027” |

64.8 |

0.084 |

| .0075” |

.026” |

59.9 |

0.111 |

| .008” |

.025” |

57.6 |

0.126 |

| .015” |

.018” |

30.1 |

0.474 |

| .016” |

.017” |

26.9 |

0.618 |

| 35 x 35 |

.011” |

.018” |

37.9 |

0.29 |

| .012” |

.017” |

33.8 |

0.35 |

| .014” |

.015” |

26.1 |

0.465 |

| 40 x 40 |

.0065” |

.019” |

54.8 |

0.113 |

| .007” |

.018” |

51.8 |

0.13 |

| .0075” |

.018” |

49 |

0.15 |

| .011” |

.014” |

31.4 |

0.338 |

| .012” |

.013” |

27 |

0.409 |

| .013” |

.012” |

23 |

0.488 |

| 50 x 50 |

.0055” |

.015” |

52.6 |

0.101 |

| .0075” |

.013” |

39.1 |

0.192 |

| .008” |

.012” |

36 |

0.221 |

| .011” |

.009” |

20.3 |

0.42 |

| .012” |

.008” |

16 |

0.511 |

| 60 x 60 |

.0045” |

.012” |

53.3 |

0.081 |

| .006” |

.011” |

41.2 |

0.147 |

| .0065” |

.010” |

37.5 |

0.174 |

| .0095” |

.007” |

18.7 |

0.379 |

| .010” |

.007” |

16.2 |

0.426 |

| .011” |

.006” |

11.7 |

0.529 |

| 70 x 70 |

.0037” |

.0106” |

54.9 |

0.06 |

| .006” |

.008” |

33.8 |

0.175 |

| .0085” |

.006” |

16.5 |

0.358 |

| .009” |

.005” |

13.8 |

0.407 |

| 80 x 80 |

.0037” |

.0088” |

49.6 |

0.069 |

| .005” |

.008” |

36 |

0.138 |

| .0055” |

.007” |

31.4 |

0.169 |

| .006” |

.007” |

27 |

0.204 |

| .0065” |

.006” |

23 |

0.232 |

| .007” |

.006” |

19.4 |

0.274 |

| .0075” |

.005” |

16 |

0.319 |

| 90 x 90 |

.0035” |

.0076” |

47.8 |

0.073 |

| .005” |

.006” |

30.1 |

0.158 |

| .0055” |

.006” |

25.4 |

0.184 |

| .006” |

.005” |

21.1 |

0.224 |

| 100 x 90 |

.004” |

.006”/.0071” |

38.5 |

0.112 |

| .0045” |

.0055”/.0066” |

32.7 |

0.117 |

| 100 x 100 |

.0022” |

.0078” |

60.8 |

0.049 |

| .003” |

.007” |

49 |

0.06 |

| .0035” |

.007” |

42.3 |

0.083 |

| .004” |

.006” |

36 |

0.11 |

| .0045” |

.006” |

30.3 |

0.142 |

| .005” |

.005” |

25 |

0.17 |

| 120 x 120 |

.0026” |

.0057” |

48.4 |

0.05 |

| .0035” |

.005” |

33.2 |

0.1 |

| .0037” |

.0046” |

30.5 |

0.103 |

| .0040” |

.0043” |

26.8 |

0.132 |

| 145 x 145 |

.0022” |

.0048” |

46.4 |

0.049 |

| 150 x 150 |

.0026” |

.0041” |

37.8 |

0.072 |

| .003” |

.0037” |

30.4 |

0.093 |

| 165 x 165 |

.0019” |

.0041” |

47.1 |

0.042 |

| 180 x 180 |

.0018” |

.0038” |

46 |

0.047 |

| .0023” |

.0033” |

34.7 |

0.067 |

| 200 x 200 |

.0016” |

.0035” |

46.2 |

0.036 |

| .0021” |

.0029” |

33.6 |

0.063 |

| .0023” |

.0027” |

49.2 |

0.073 |

| 230 x 230 |

.0014” |

.0029” |

46 |

0.031 |

| 250 x 250 |

.0014” |

.0026” |

42.3 |

0.035 |

| .0016” |

.0024” |

36 |

0.041 |

| 270 x 270 |

.0014” |

.0023” |

38.6 |

0.037 |

| .0016” |

.0021” |

32.1 |

0.048 |

| 280 x 280 |

.0014” |

.0022” |

38 |

0.039 |

| 300 x 300 |

.0012” |

.0021” |

41 |

0.03 |

| .0015” |

.0018” |

29.2 |

0.047 |

| 325 x 325 |

.0011” |

.0020” |

41.6 |

0.029 |

| .0014” |

.0017” |

30.5 |

0.043 |

| 400 x 400 |

.0010” |

.0015” |

38 |

0.028 |

| .0011” |

.0014” |

31.4 |

0.034 |

| 500 x 500 |

.0010” |

.0010” |

26 |

0.033 |

| 635 x 635 |

.0008” |

.0008” |

25.8 |

0.027 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!