Product Description:

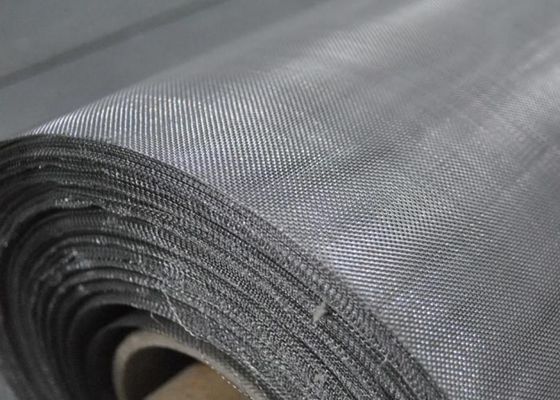

Stainless steel wire mesh, also known as stainless steel woven wire mesh or stainless steel wire cloth, refers to a versatile and durable material composed of interwoven stainless steel wires. It is created through the process of weaving, where the wires are systematically interlaced to form a mesh pattern with uniform openings.

Stainless steel wire mesh is manufactured using high-quality stainless steel wires that are corrosion-resistant and offer excellent strength. The wires are typically drawn to precise diameters and then woven together to create a mesh structure with specific aperture sizes, which determine the filtration or sieving capabilities of the mesh.

The weave patterns used in stainless steel wire mesh can vary, with common options including plain weave, twill weave, and Dutch weave. Each weave pattern offers different characteristics in terms of strength, open area, and filtration properties.

Stainless steel wire mesh is available in a wide range of mesh sizes, which refers to the number of openings per linear inch. Mesh sizes can range from coarse to fine, allowing for precise control over the size of particles or substances that can pass through the mesh.

The properties of stainless steel wire mesh make it highly suitable for various applications across industries. It is valued for its corrosion resistance, durability, precise filtration capabilities, and high tensile strength. Stainless steel wire mesh finds applications in areas such as chemical processing, pharmaceuticals, food and beverage, mining, oil and gas, automotive, architecture, and more. It is used for filtration, sieving, separation, protection, ventilation, insect screening, and other processes that require reliable and efficient material with precise control over particle size or substance flow.

Overall, stainless steel wire mesh is a versatile and dependable material that offers excellent performance in demanding industrial environments, making it a popular choice for numerous applications requiring reliable filtration or sieving capabilities.

Features:

-

Material: Stainless steel wire mesh screens are made from stainless steel, which provides excellent corrosion resistance and durability.

-

Mesh Size: The mesh size refers to the number of openings per linear inch. It determines the screen's aperture size and defines its filtration or sieving capabilities. Stainless steel wire mesh screens are available in various mesh sizes, ranging from coarse to fine. Common mesh sizes include 10 mesh, 20 mesh, 40 mesh, 60 mesh, 100 mesh, 200 mesh, 400 mesh, and higher.

-

Wire Diameter: The wire diameter refers to the thickness of the wires used in constructing the mesh screen. It affects the strength of the screen and the size of the openings. Stainless steel wire mesh screens typically have uniform wire diameters, ensuring consistent aperture size throughout the screen.

-

Weave Type: Stainless steel wire mesh screens can be manufactured using different weave types, such as plain weave, twill weave, or Dutch weave. Each weave type has its own pattern and characteristics, affecting the screen's strength, open area, and filtration properties.

-

Open Area: The open area of a mesh screen refers to the percentage of open space compared to the total surface area. It determines the flow rate and permeability of the screen. Finer mesh screens generally have lower open areas due to the smaller openings between wires.

-

Tensile Strength: Stainless steel wire mesh screens exhibit high tensile strength, allowing them to withstand mechanical stress and maintain their structural integrity even under tension.

-

Corrosion Resistance: Stainless steel is known for its excellent corrosion resistance, making stainless steel wire mesh screens suitable for use in harsh or corrosive environments. The specific level of corrosion resistance can vary depending on the grade of stainless steel used.

-

Temperature Resistance: Stainless steel wire mesh screens can withstand high temperatures without significant deformation or degradation, making them suitable for applications involving heat or thermal processes.

-

Surface Finish: Stainless steel wire mesh screens can have different surface finishes, such as plain, bright, or matte. The surface finish can impact the screen's appearance, ease of cleaning, and performance in specific applications.

Technical Parameters:

| Mesh Count |

Plain Weave Wire Mesh Can Be Woven Up To 400 Mesh. Twill Weave Wire Mesh Can Be Woven From 30 To 635 Mesh. |

| Width |

0.03m-6.5m |

| Mesh Size |

0.03-50.8mm |

| Aperture |

0.02-50.8mm |

| Length |

1m-300m |

| Material |

SS Wire 201, 304, 304L, 316, 316L, 431, 321 347 Etc. |

| Edge Treatment |

Raw Edge, Selvadge |

| Features |

Flat, Solid, Corrosion Resistance, Oxidation Resistance |

| Weave Type |

Plain Weave, Twilled Weave, Dutch Weave |

| Wire Diameter |

0.02mm-5mm |

Applications:

Filtration and Separation: Stainless steel wire mesh is extensively used for filtration and separation processes in industries such as chemical processing, pharmaceuticals, food and beverage, oil and gas, and water treatment. It effectively filters out solid particles, contaminants, and impurities from liquids, gases, and air, ensuring product quality, process efficiency, and equipment protection.

Sieving and Sifting: Stainless steel wire mesh is utilized for sieving and sifting applications, where it acts as a reliable screening medium. It is commonly employed in the mining and aggregate industries to sieve and classify minerals, rocks, and aggregates based on their particle size. It is also used in the construction industry for soil sieving and grading.

Protection and Safety: Stainless steel wire mesh provides protection and safety in various applications. It is used as window screens, door screens, and insect screens to prevent insects, pests, and debris from entering residential, commercial, and industrial spaces while maintaining proper ventilation. Stainless steel mesh is also employed as safety barriers, machine guards, and fencing to ensure worker safety and restrict access to hazardous areas.

Architectural Applications: Stainless steel wire mesh is utilized in architectural applications for its aesthetic appeal and functionality. It is employed as decorative mesh in building facades, sunscreens, balustrades, and interior design elements to provide an elegant and modern look. Stainless steel wire mesh can also be used for shading, privacy screens, and acoustic panels in architectural projects.

Heat Treatment and Thermal Processes: Due to its excellent heat and temperature resistance, stainless steel wire mesh is suitable for applications involving heat treatment, thermal processes, and high-temperature environments. It is used in heat exchangers, furnace screens, and thermal insulation blankets to withstand elevated temperatures while allowing efficient heat transfer.

Automotive Industry: Stainless steel wire mesh finds applications in the automotive industry for various purposes. It is used as filters in fuel systems, air intake systems, and oil filters to ensure clean and efficient operation. Stainless steel mesh is also employed in exhaust systems to minimize noise and facilitate proper gas flow.

Support and Services:

Our Stainless Steel Wire Mesh Screen product comes with comprehensive technical support and services to ensure that you have the best experience possible. Our team of experts can assist you with any questions or concerns that you may have regarding the installation, operation, and maintenance of the product. In addition, we offer repair and replacement services for any defective or damaged items. Our goal is to provide you with a reliable and durable product that meets your specific needs and requirements. Contact us for more information on our technical support and services.

Packing and Shipping:

Product Packaging:

- Each stainless steel wire mesh screen is individually wrapped in plastic

- Multiple screens are then placed in a sturdy cardboard box with foam padding

- The box is sealed with heavy-duty tape to ensure safe transport

Shipping:

- Orders will be processed within 1-2 business days

- Shipping time may vary depending on the destination

- Customers will receive a tracking number once the order has shipped

- International shipping is available for an additional fee

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!