Product Description:

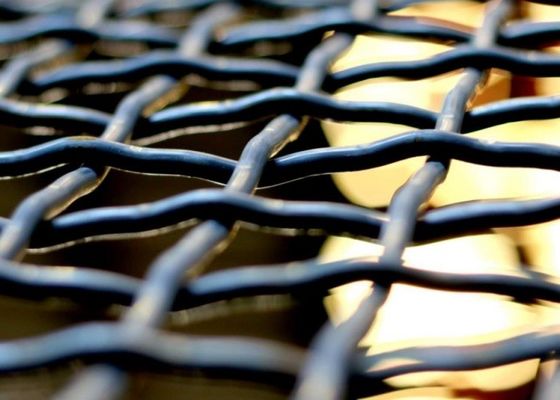

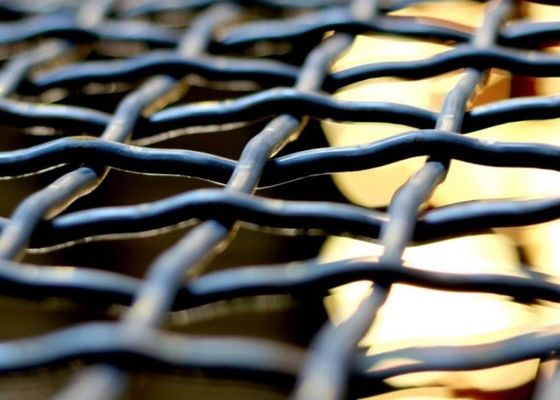

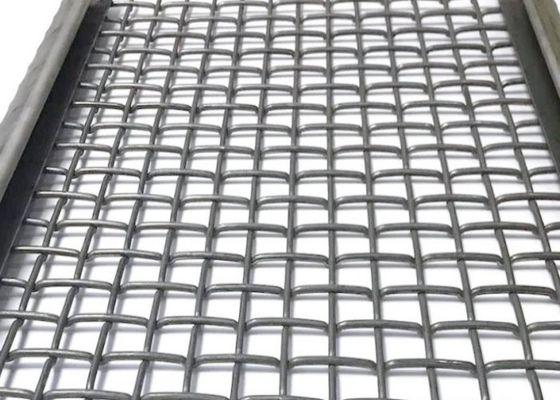

With an opening size of 1mm to 100mm, the Woven Wire Mesh Screen comes in different weaving types such as plain, twilled, Dutch, and crimped. This allows for flexibility in its application and ensures that it can cater to different screening requirements.

The Woven Wire Mesh Screen comes in different surface treatments such as galvanized, PVC coated, and epoxy coated. This surface treatment enhances the product's resistance to corrosion and rust, making it ideal for outdoor and harsh environments.

This product is made of high carbon steel, manganese steel, and stainless steel, making it suitable for heavy-duty applications. The high carbon steel material is known for its strength and toughness, ensuring that the Woven Wire Mesh Screen can withstand high impact and heavy loads.

The Woven Wire Mesh Screen can be used for various applications such as quarry screen, crusher screen, and separation or filtration in the chemical oil industries and other industries that require screening solutions. Its high-quality material and construction make it an excellent choice for vibrating screens that require durability and strength.

Overall, the Woven Wire Mesh Screen is a reliable and efficient screening solution that is suitable for various applications. Its different weaving types, opening sizes, and surface treatments make it a versatile product that can cater to different screening requirements. Its high-quality construction and material ensure that it can withstand heavy loads and high impact, making it an ideal choice for vibrating screens that require durability and strength.

Features:

Woven wire mesh screens are commonly used in various industrial applications, including abrasion-resistant applications. When selecting a woven wire mesh screen for such purposes, there are several features to consider. Here are some key features of woven wire mesh screens for abrasion-resistant applications:

- Material Selection: The choice of material for the wire mesh screen is crucial for abrasion resistance. Common materials used for abrasion-resistant screens include stainless steel, high-carbon steel, and specialty alloys such as Inconel or Monel. These materials offer excellent strength and durability to withstand abrasive forces.

- Wire Diameter and Mesh Count: The wire diameter and mesh count determine the screen's openness and the size of particles it can effectively filter. In abrasion-resistant applications, screens with thicker wire diameters and lower mesh counts are generally preferred as they offer greater strength and resistance to wear and tear.

- Weave Type: The weave type of the wire mesh screen affects its mechanical properties and abrasion resistance. Some commonly used weave types for abrasion-resistant applications include plain weave, twill weave, and Dutch weave. Each weave type offers different levels of strength, particle retention, and resistance to deformation.

- Surface Treatment: Surface treatments can enhance the abrasion resistance of wire mesh screens. Coatings such as galvanization, epoxy resin, or polymer coatings can provide an additional layer of protection against abrasion, corrosion, and other environmental factors.

- Tensile Strength: The tensile strength of the wire mesh screen is crucial to withstand the forces exerted during abrasive operations. It is essential to choose a screen with high tensile strength to prevent premature failure or deformation.

- Customization Options: Depending on the specific application requirements, woven wire mesh screens can be customized in terms of size, shape, and configuration. Customization allows for a better fit within the machinery or equipment and ensures optimal performance in abrasion-resistant applications.

Technical Parameters:

| Applications |

Quarry Screen, Crusher Screen, Seperation Or Filtration In Chemical Oil, Industries And So On |

| Weaving type |

Plain, Twilled, Dutch, Cripmed |

| Material |

High Tensile Spring Steel, Manganese Steel And Stainless Steel |

| Surface treatment |

Galvanized, PVC Coated, Epoxy Coated |

| Mesh type |

Square, Rectangular |

| Edge preparation |

Plain, Selvage, Raw Edge |

| Features |

Abrasion Resistant, Heavy Impact Resistant, Corrosion Resistant,Long Service Life |

Applications:

Abrasion-resistant woven wire mesh screens find applications in various industries where protection against abrasive forces is required. Here are some common applications of these screens:

Mining and Quarrying: Woven wire mesh screens are extensively used in the mining and quarrying industry to withstand the abrasive impact of rocks, minerals, and other materials. They are used as vibrating screens, trommel screens, and scalping screens in processes such as screening, grading, and separating ore, coal, gravel, sand, and aggregates.

Construction and Infrastructure: In the construction industry, abrasion-resistant wire mesh screens are used for reinforcing concrete structures. They provide strength and durability to concrete and prevent cracking or spalling caused by abrasive materials or environmental factors.

Recycling and Waste Management: Woven wire mesh screens are employed in recycling and waste management facilities to sort and separate different types of materials. They are used in trommel screens, sorting screens, and vibrating screens to separate recyclable materials, such as paper, plastics, metals, and glass, from waste streams.

Chemical and Petrochemical Industry: Abrasion-resistant wire mesh screens are utilized in the chemical and petrochemical industry to filter and separate abrasive chemicals, catalysts, abrasive powders, and other substances in various processes. They are also used in reactors, separators, and filtration systems.

Food Processing: In the food industry, woven wire mesh screens with abrasion resistance are employed for sifting, grading, and separating food products. They are used in vibrating screens, dewatering screens, and sieving screens to process ingredients, grains, spices, and other food materials.

Aggregate Processing: Woven wire mesh screens are widely used in the aggregate processing industry for sizing and separating crushed stones, sand, and gravel. They are employed in vibrating screens, trommel screens, and dewatering screens to achieve the desired particle size distribution.

Pulp and Paper Industry: In the pulp and paper industry, abrasion-resistant wire mesh screens are used in various stages of the production process. They are employed in screens, filters, and separators to remove contaminants, fibers, and impurities from the pulp or paper.

Ceramic and Glass Industry: Woven wire mesh screens find applications in the ceramic and glass industry for sieving and classifying powders, particles, and granules. They are used in vibrating screens, fluid bed dryers, and filtration systems to ensure product quality and remove impurities.

FAQ:

Q: What is the brand name of the woven wire mesh screen product?

A: The brand name of the woven wire mesh screen product is Kingdelong.

Q: What is the model number of the woven wire mesh screen product?

A: The model number of the woven wire mesh screen product is KDL.

Q: What is the place of origin of the woven wire mesh screen product?

A: The place of origin of the woven wire mesh screen product is Anping, China.

Q: What certifications does the woven wire mesh screen product have?

A: The woven wire mesh screen product is certified with ISO9001, ISO14001, ISO45001, and SGS.

Q: What is the minimum order quantity for the woven wire mesh screen product?

A: The minimum order quantity for the woven wire mesh screen product is 30sqm.

Q: What is the price range of the woven wire mesh screen product?

A: The price range of the woven wire mesh screen product is $75-$110.

Q: What are the packaging details for the woven wire mesh screen product?

A: The woven wire mesh screen product is rolled around a paper tube first, and then covered with moisture-proof paper outside or plastic fabrics. Customized packing is also available.

Q: What is the delivery time for the woven wire mesh screen product?

A: The delivery time for the woven wire mesh screen product is 5 to 7 days, if in stock.

Q: What are the payment terms for the woven wire mesh screen product?

A: The payment terms for the woven wire mesh screen product are D/P, T/T, and D/A.

Q: What is the supply ability of the woven wire mesh screen product?

A: The supply ability of the woven wire mesh screen product is 10000sqm.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!