Product Description:

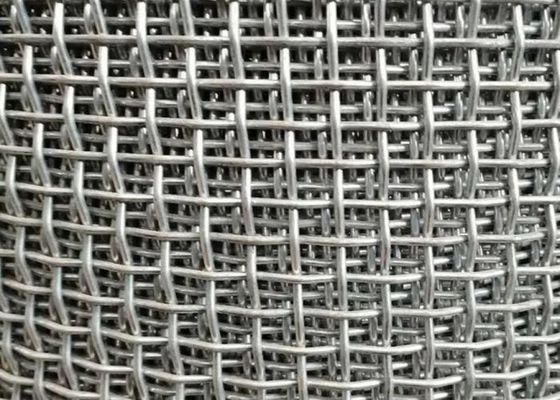

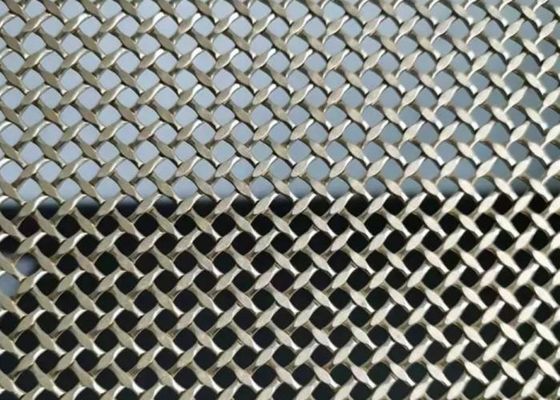

The mesh screen is constructed using high carbon steel wires that are woven together to form a square hole pattern. This design offers several advantages. The square holes provide a larger open area, allowing for efficient material flow and improved screening or filtration processes. The shape of the openings also helps prevent clogging and blinding, ensuring uninterrupted operation. It is specifically designed to withstand harsh industrial environments where abrasion resistance is crucial. The mesh screen is constructed using high carbon steel wires woven together in a square hole pattern. This design offers several advantages. Firstly, the square holes provide a larger open area, allowing for efficient material flow and improved screening or filtration processes. The shape of the openings also helps prevent clogging and blinding, ensuring uninterrupted operation. The mesh screen is made from high carbon steel wires known for their hardness and toughness. This enables the screen to withstand the impact and abrasive forces of heavy materials or particles, making it highly resistant to wear. It's an ideal choice for industries such as mining, quarrying, and aggregate processing, where the mesh screen is exposed to abrasive materials or high-wear conditions. KDL offers customization options for wire diameter and mesh size to ensure the mesh screen meets your exact specifications. To proceed with your purchase, KDL team can discuss the specific dimensions and customization options you require. Meantime, KDL team will assist you with pricing, delivery, and any other questions you may have too.

Features:

- Product Name: Abrasion Resistance Square Hole High Carbon Steel Woven Wire Mesh Screen

- Edge preparation: Plain, Selvage, Raw Edge, etc

- Opening size: 0.002mm - 16mm

- Surface treatment: Galvanized, PVC Coated, Epoxy Coated, etct

- Material: High carbon steel , SS 304, SS 316, etct

- Weaving type: Plain, Twilled, Dutch, Cripmed, etct

This Woven Wire Mesh Screen product is ideal for use as a Vibrating Screen due to its:

- High Carbon Steel material

- Variety of opening sizes

- Range of surface treatments

- Multiple edge preparation options

- Different weaving types available

Technical Parameters:

Parameter | Description |

|---|

| Material | High carbon steel, SS 304, SS 316, etc |

| Wire Diameter | 0.5 mm (0.0197 inches) to 5 mm (0.197 inches), or custom |

| Mesh Count | 1-2800 |

| Opening Size | 0.002mm-16mm |

| Tensile Strength | Varies based on wire diameter and material |

| Open Area | 2.5%-86% |

| Surface Treatment | None or optional coatings for corrosion resistance or surface characteristics |

Applications:

Mining and Quarrying: The mesh screen is used in mining operations and quarries for material separation, sizing, and classification. It is effective in screening and separating ores, minerals, and aggregates, even in high-wear conditions.

Aggregate Processing: In the construction industry, the mesh screen is employed in aggregate processing plants for efficient separation of different-sized materials. It withstands the abrasive nature of rocks, gravel, and sand.

Cement and Concrete Manufacturing: The mesh screen is utilized in cement and concrete manufacturing processes to separate and classify raw materials, such as limestone, sand, and aggregates.

Recycling and Waste Management: It is used in recycling and waste management facilities to sort and separate various materials like plastics, paper, metals, and more. The high abrasion resistance makes it suitable for handling and processing abrasive recyclable materials.

Chemical and Pharmaceutical Industries: The mesh screen finds application in chemical and pharmaceutical processing, where it is used for filtration, separation, and sieving of powders, granules, and liquids.

Food Processing: In the food industry, the mesh screen is employed for sieving and grading food products, such as grains, flour, sugar, and spices. It ensures efficient particle separation and maintains hygiene standards.

Construction and Infrastructure: The mesh screen is utilized in construction and infrastructure projects for reinforcement purposes, such as reinforcing concrete structures or providing safety and perimeter fencing.

Industrial Filtration: It is used in various industrial filtration systems to remove impurities, particulate matter, and debris from liquids and gases. The high abrasion resistance allows it to withstand the demanding filtration processes.

Packing and Shipping:

Product Packaging:

- The woven wire mesh screen will be carefully wrapped in a protective plastic film to prevent any scratches or damage during shipping.

- The screen will then be placed inside a sturdy cardboard box with additional padding to ensure it stays in place and is protected during transit.

- The box will be clearly labeled with the product name, size, and any other relevant information.

Shipping:

- The woven wire mesh screen will be shipped via a reputable courier service, such as UPS or FedEx.

- Customers will receive a tracking number once the order has been processed and shipped.

- Shipping times may vary depending on the destination, but we aim to deliver all orders within 3-5 business days.

FAQ:

Q1: What certifications does the Woven Wire Mesh Screen have?

A1: The Woven Wire Mesh Screen has ISO9001, ISO14001, ISO45001, and SGS certifications.

Q2: What is the minimum order quantity for the Woven Wire Mesh Screen?

A2: The minimum order quantity is 30sqm and the price ranges from $75 to $110.

Q3: What is the advantage of using a Square Hole Woven Wire Mesh Screen?

A3: The square hole design offers a larger open area compared to other mesh patterns, allowing for improved material flow and efficient screening or filtration processes.

Q4: What materials are commonly used for Square Hole Woven Wire Mesh Screens?

A4: Square Hole Woven Wire Mesh Screens are often made from high carbon steel. Other materials such as stainless steel, brass, or copper can also be used.

Q5: What are the typical applications of Square Hole Woven Wire Mesh Screens?

A5: They are used for material separation, sizing, classification, reinforcement, safety fencing, and filtration purposes.

Q6: Can Square Hole Woven Wire Mesh Screens be customized?

A6: Yes, they can be customized based on wire diameter, mesh count, and opening size to meet specific requirements.

Q7: Are Square Hole Woven Wire Mesh Screens available in different sizes?

A7: Yes, Square Hole Woven Wire Mesh Screens are available in various sizes, including different wire diameters and mesh counts.

Q8: Can Square Hole Woven Wire Mesh Screens withstand abrasive materials?

A8: Yes. They can withstand the impact and abrasive forces caused by heavy materials or particles, making them suitable for applications involving abrasive materials.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!