904L Stainless Steel Woven Wire Mesh with Superior Corrosion Resistance

904L is a special type of austenitic stainless steel, with low carbon, high nickel, and molybdenum. It contains about 21% chromium, 25.5% nickel, 4.5% molybdenum, and 1.5% copper.

The high content of chromium, nickel, and molybdenum (the nickel and molybdenum content is almost twice 316L) makes its superior resistance against corrosion, better performance under high-temperature oxidation, and further enhances its resistance to pitting and crevice corrosion. Also, the addition of copper makes it more suitable for all concentrations of sulfuric acid.

It is an ideal material for various different environments, especially inorganic acid and organic acid environments. In a neutral medium chlorine ion environment, it even has excellent pitting corrosion resistance.

| 904L Stainless Steel - Chemical Compositions |

| C |

Cr |

Cu |

Pb |

Mn |

Ni |

P |

Si |

S |

Sn |

| 0.08% |

17 – 20% |

1% |

0.01% |

2% |

34-37% |

0.03% |

0.75-1.5 % |

0.03% |

0.03% |

Key Features

Good Resistance against Stress Corrosion, Cracking

Superior Mechanical and Physical Properties

Great hardness below cryogenic temperatures

Thermal stability

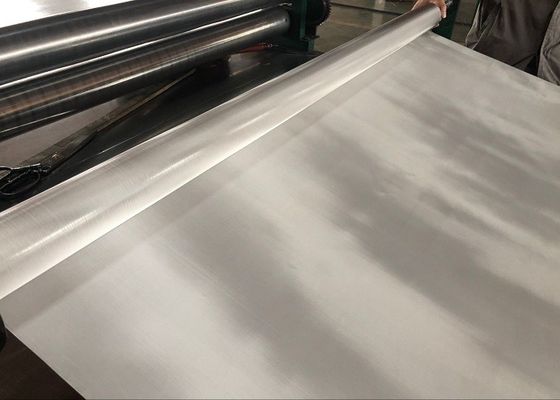

Incredible Finish

904L Stainless Steel Wire Mesh is available in both woven and welded types, including all woven types, such as plain weave, twilled weave, dutch weave, and reversed dutch weave. Because of the super material, the mesh also displays super excellent corrosion resistance in severe industrial and chemical environments. It also provides excellent corrosion resistance in sulfuric, phosphoric, and acetic acid solutions and prevents pitting corrosion attacks in chloride conditions.

Here are some very commonly used 904L Stainless Steel Woven Wire Mesh specifications, just for your reference. Other specifications, sizes, and woven types are made to order. Please contact our sales team to discuss this.

| Mesh |

Wire diameter |

Aperture/Opening |

Open Area % |

| Inch |

Mm |

Inch |

Mm |

| 1X1 |

0.08 |

2.03 |

0.92 |

23.37 |

84.6 |

| 2X2 |

0.063 |

1.6 |

0.437 |

11.1 |

76.4 |

| 3X3 |

0.054 |

1.37 |

0.279 |

7.09 |

70.1 |

| 4X4 |

0.063 |

1.6 |

0.187 |

4.75 |

56 |

| 4X4 |

0.047 |

1.19 |

0.203 |

5.16 |

65.9 |

| 5X5 |

0.041 |

1.04 |

0.159 |

4.04 |

63.2 |

| 6X6 |

0.035 |

0.89 |

0.132 |

3.35 |

62.7 |

| 8X8 |

0.028 |

0.71 |

0.097 |

2.46 |

60.2 |

| 10X10 |

0.025 |

0.64 |

0.075 |

1.91 |

56.3 |

| 10X10 |

0.02 |

0.51 |

0.08 |

2.03 |

64 |

| 12X12 |

0.023 |

0.584 |

0.06 |

1.52 |

51.8 |

| 12X12 |

0.02 |

0.508 |

0.063 |

1.6 |

57.2 |

| 14X14 |

0.023 |

0.584 |

0.048 |

1.22 |

45.2 |

| 14X14 |

0.02 |

0.508 |

0.051 |

1.3 |

51 |

| 16X16 |

0.018 |

0.457 |

0.0445 |

1.13 |

50.7 |

| 18X18 |

0.017 |

0.432 |

0.0386 |

0.98 |

48.3 |

| 20X20 |

0.02 |

0.508 |

0.03 |

0.76 |

36 |

| 20X20 |

0.016 |

0.406 |

0.034 |

0.86 |

46.2 |

| 24X24 |

0.014 |

0.356 |

0.0277 |

0.7 |

44.2 |

| 30X30 |

0.013 |

0.33 |

0.0203 |

0.52 |

37.1 |

| 30X30 |

0.012 |

0.305 |

0.0213 |

0.54 |

40.8 |

| 30X30 |

0.009 |

0.229 |

0.0243 |

0.62 |

53.1 |

| 35X35 |

0.011 |

0.279 |

0.0176 |

0.45 |

37.9 |

| 40X40 |

0.01 |

0.254 |

0.015 |

0.38 |

36 |

| 50X50 |

0.009 |

0.229 |

0.011 |

0.28 |

30.3 |

| 50X50 |

0.008 |

0.203 |

0.012 |

0.31 |

36 |

| 60X60 |

0.0075 |

0.191 |

0.0092 |

0.23 |

30.5 |

| 60X60 |

0.007 |

0.178 |

0.0097 |

0.25 |

33.9 |

| 70X70 |

0.0065 |

0.165 |

0.0078 |

0.2 |

29.8 |

| 80X80 |

0.0065 |

0.165 |

0.006 |

0.15 |

23 |

| 80X80 |

0.0055 |

0.14 |

0.007 |

0.18 |

31.4 |

| 90X90 |

0.005 |

0.127 |

0.0061 |

0.16 |

30.1 |

| 100X100 |

0.0045 |

0.114 |

0.0055 |

0.14 |

30.3 |

| 100X100 |

0.004 |

0.102 |

0.006 |

0.15 |

36 |

| 100X100 |

0.0035 |

0.089 |

0.0065 |

0.17 |

42.3 |

| 110X110 |

0.004 |

0.1016 |

0.0051 |

0.1295 |

30.7 |

| 120X120 |

0.0037 |

0.094 |

0.0046 |

0.1168 |

30.7 |

| 150X150 |

0.0026 |

0.066 |

0.0041 |

0.1041 |

37.4 |

| 160X160 |

0.0025 |

0.0635 |

0.0038 |

0.0965 |

36.4 |

| 180X180 |

0.0023 |

0.0584 |

0.0033 |

0.0838 |

34.7 |

| 200X200 |

0.0021 |

0.0533 |

0.0029 |

0.0737 |

33.6 |

| 250X250 |

0.0016 |

0.0406 |

0.0024 |

0.061 |

36 |

Attention

Be careful of the cutting sharp edge, and avoid getting hurt while open and use.

Before you order your mesh, please first check out our stock list, where we put our over-run bargain rolls at lower prices.

Main Applications

Medical

Chemical

Petrochemical

Oil and Gas Wells

Food Processing(especially for pickled food),

Sea Water and Waste Water Treatment Industry

King De Long Company is a Very Good Manufacturer of Woven Wire Mesh

King De Long Wire Mesh just started from a small workshop in 1986, after so many years of development, it is now over 266,400 m2. There are more than 400 sets of working machines, including wire-drawing, annealing, weaving, welding, cutting, punching, slitting machines, and so on.

There are special types of equipment to check raw wires, including chemical composition, tensile strength, yield strength, etc. And our experienced worker team, who have worked in the wire mesh field for 10 years at least, 24 hours 3 working shifts, could ensure we finish your order in time with good quality.

There is a department in our factory to handle the Stamping, Shearing, Welding, Punching, etc, to produce small discs, filters, strainers, baskets, cylinders, and screens to your exact specifications. Should you have a particular specification in mind, please contact us to discuss your requirements.

For your reference, some photos of our products and factory are listed here, please check.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!