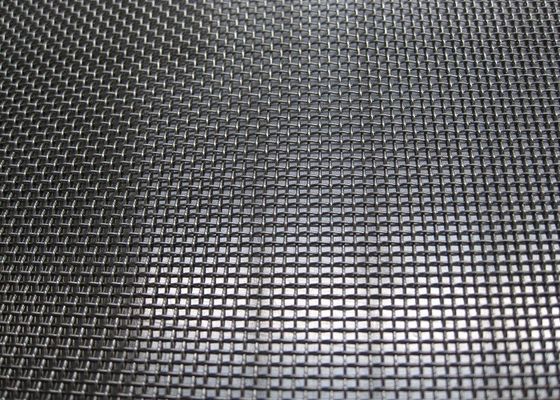

Inconel600 Woven Wire Mesh Used in High-Temperature Environments

Inconel is a nickel-chromium alloy, which can offer great resistance to corrosion and high temperatures. So, it is normally used in a wide range of severe environments, where is high temperature, with various alkaline salt solutions, caustic, oxidizing, sulfur compounds and etc.

With these advantages, Inconel alloy wire mesh is widely used in chemical processing, pressure valve, and heat exchanger applications. Inconel 600, Inconel 601(with added Aluminum), and Inconel 625 (with added Molybdenum and Niobium) are the very common Inconel material for wire mesh; the difference between these grades is in their individual chemical composition. The addition of some elements will impact its characteristics in different environments.

Here below are the special chemical compositions of the common Inconel alloys.

| Typical Inconel Alloy Chemical Composition (%) |

| Grade |

Al |

C |

Cb |

Co |

Cr |

Cu |

Fe |

Mn |

Mo |

Nb |

Ni |

P |

S |

Si |

Ti |

| 600 |

/ |

0.15 |

/ |

/ |

14.0-17.0 |

0.5 |

6.0-10.0 |

1 |

/ |

/ |

72 |

/ |

0.015 |

0.5 |

/ |

| 601 |

1.0-1.7 |

0.1 |

/ |

/ |

21.0-25.0 |

1 |

Balance |

1 |

/ |

/ |

58.0-63.0 |

/ |

0.015 |

0.5 |

/ |

| 625 |

0.4 |

0.1 |

3.15-4.15 |

1 |

20.0-23.0 |

/ |

5 |

0.5 |

8.0-10.0 |

3.15-4.15 |

Balance |

0.015 |

0.015 |

0.5 |

0.4 |

Inconel 600 can be used in environments with temperatures ranging from cryogenic to 2050°F. Its high nickel (~76%) content gives Alloy 600 wire cloth excellent resistance to alkaline solutions, reducing conditions, chloride stress-corrosion cracking, and a wide array of inorganic and organic compounds. Its high chromium (~15.5%) content gives Inconel 600 wire mesh good resistance to various alkaline salt solutions, caustic environments, oxidizing environments, and sulfur compounds.

Industries and Applications

Inconel 600 wire mesh is principally used in high-temperature environments that also present corrosive, oxidizing, or reducing agents. And also, Alloy 600 is widely used in heat-treating equipment, muffle furnaces, nuclear steam, and generator equipment. Besides, it could also be used in electronic components, chemical and food processing, gas turbine components, pulp, paper-making processing, etc.

Here are some very normal specifications of the Inconel600 woven wire mesh for your reference.

Other specifications and sizes are made to order. Please contact our sales team to discuss this.

| Mesh No. |

Wire Diam./MM |

APERTURE/MM |

Open Area % |

Weight kg/sqm |

| 4x4 |

1.25 |

5.1 |

64.5 |

3.125 |

| 5x5 |

1 |

4.08 |

64.5 |

2.5 |

| 6x6 |

0.8 |

3.43 |

65.75 |

1.92 |

| 8x8 |

0.7 |

2.48 |

60.82 |

1.96 |

| 10x10 |

0.6 |

1.94 |

58.34 |

1.8 |

| 12x12 |

0.4 |

1.72 |

65.82 |

0.96 |

| 12x12 |

0.6 |

1.52 |

51.41 |

2.16 |

| 14x14 |

0.3 |

1.51 |

69.6 |

0.63 |

| 16x16 |

0.25 |

1.34 |

71.03 |

0.5 |

| 18x18 |

0.3 |

1.11 |

61.97 |

0.81 |

| 20x20 |

0.3 |

0.97 |

58.34 |

0.9 |

| 25x25 |

0.3 |

0.72 |

49.83 |

1.125 |

| 30x30 |

0.23 |

0.62 |

53.2 |

0.794 |

| 40x40 |

0.2 |

0.44 |

47.27 |

0.8 |

| 50x50 |

0.2 |

0.31 |

36.95 |

1 |

| 60x60 |

0.15 |

0.27 |

41.33 |

0.675 |

| 80x80 |

0.12 |

0.2 |

39.06 |

0.576 |

| 100x100 |

0.1 |

0.154 |

36.76 |

0.5 |

| 120x120 |

0.081 |

0.131 |

38.18 |

0.394 |

Attention

Be careful of the cutting sharp edge, and avoid getting hurt while open and use.

Before you order your mesh, please first check out our stock list, where we put our over-run bargain rolls at lower prices.

For your reference, some photos of our products and factory are listed here, please check.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!